Page 9 - bpk_brill

P. 9

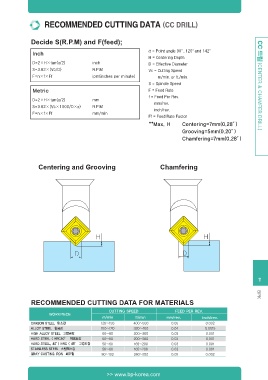

RECOMMENDED CUTTING DATA (CC DRILL)

Decide S(R.P.M) and F(feed); CC 드릴 (CENTER & CHAMFER DRILL)

Inch inch α= Point angle 90°, 120°and 142°

R.P.M

D=2×H×tan(α/2) ipm(inches per minute) H = Centering Depth

S=3.82×(Vc/D) D = Effective Diameter

F=n×f×Ff Vc = Cutting Speed

Metric mm m/min. or ft./min.

R.P.M S = Spindle Speed

D=2×H×tan(α/2) mm/min F = Feed Rate

S=3.82×(Vc×1000/D×π) f = Feed Per Rev.

F=n×f×Ff

mm/rev.

inch/rev.

Ff = Feed Rate Factor

**Max. H Centering=7mm(0.28″)

Grooving=5mm(0.20″)

Chamfering=7mm(0.28″)

Centering and Grooving Chamfering

11

ReCoMMenDeD CuttInG DAtA FoR MAteRIAlS

WORKPIECE CUTTING SPEED FEED PER REV.

CARBON STEEL 탄소강 m/min ft/min mm/rev. inch/rev.

ALLOy STEEL 합금강

HIGH ALLOy STEEL 고합금강 120~150 400~500 0.05 0.002

HARD STEEL < HRC40° 저경도강 0.04 0.0015

HARD STEEL, 40°< HRC < 48° 고경도강 100~120 330~400 0.03 0.001

STAINLESS STEEL 스텐레스강 60~80 200~260 0.03 0.001

GRAy CASTING IRON 회주철 60~80 200~260 0.03 0.001

0.03 0.001

50~60 165~200 0.05 0.002

50~60 165~200

80~102 260~332

>> www.bp-korea.com